Complete History

Access all your past replenishments without time limit. Perfect for audits and historical analysis.

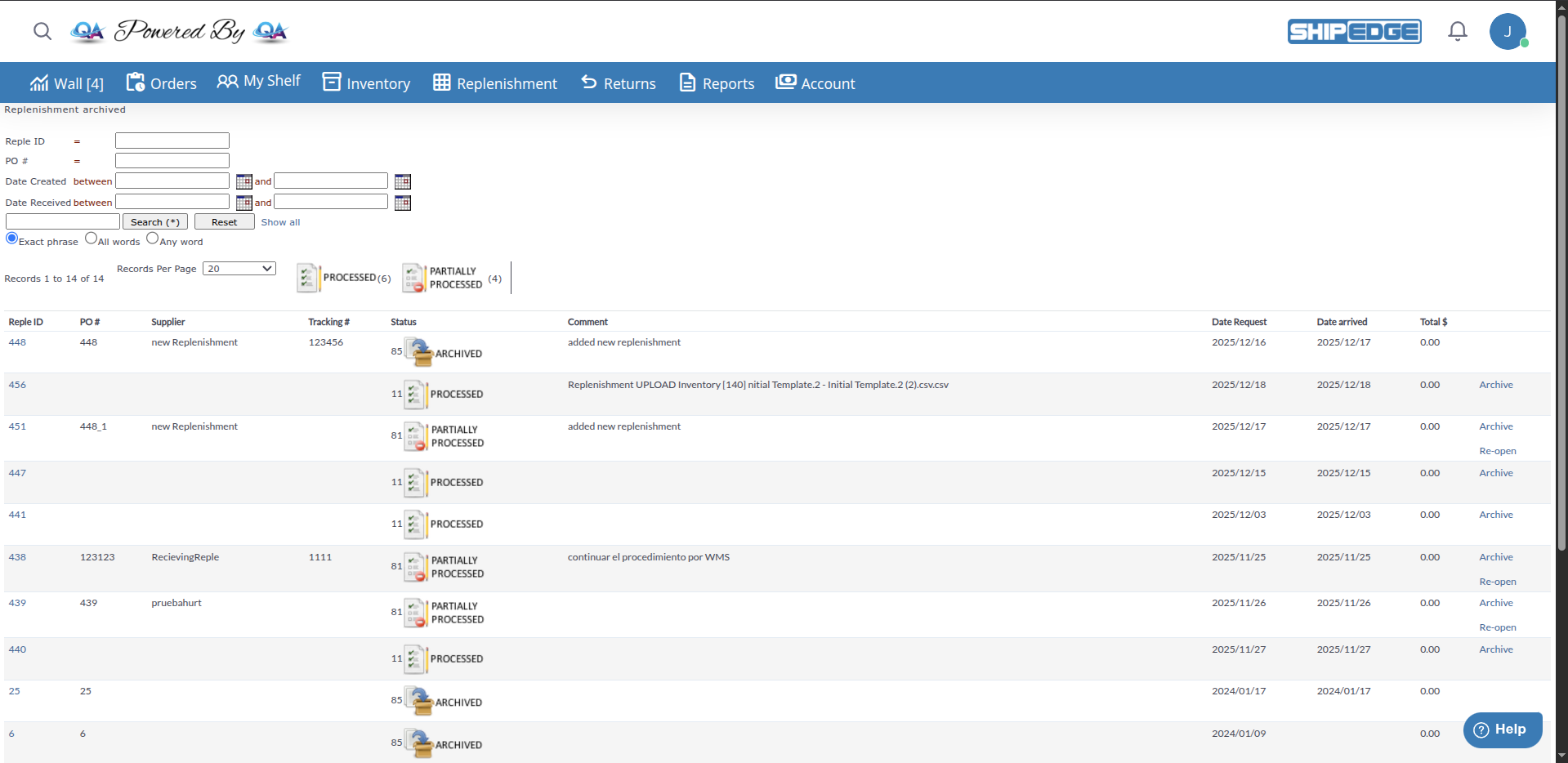

Archived Replenishments is the history view where all replenishments that have been completed, processed, or partially processed are stored. This view allows you to review past shipments, verify what was received, track costs, and mark orders as paid for accounting control.

Once a replenishment has been completed (all inventory received and placed in bins), it automatically moves to the archived section. This keeps your active replenishments list clean and organized, while preserving all history for auditing and analysis.

Access all your past replenishments without time limit. Perfect for audits and historical analysis.

Mark orders as paid for accounting control and avoid duplicate payments to suppliers.

Filter by RequestID, PO#, supplier, dates, status, and more to quickly find specific receipts.

View total cost of each received replenishment for expense analysis and forecasting.

Review exactly which SKUs and quantities were received in past shipments.

Export your history to CSV for external reports, Excel analysis, or integration with accounting systems.

Replenishments are automatically archived when:

When all expected inventory was received and processed:

When you received less than expected and decided to close the replenishment:

When you mark a replenishment as paid to supplier:

Navigate to Replenishments Module

From the main menu, go to Inventory → Replenishments or search for “Replenishment”.

Click the Archived Link

In the main replenishments view, look for the link or button that says:

Archived History

You’ll See the List of Archived Replenishments

The system displays a table with all completed replenishments, showing:

The table shows columns with key information from each archived replenishment:

The unique ID of the replenishment. Click it to see complete details (which SKUs were received, quantities, bins, etc.).

Example: 12345, 67890

Use: Identifier to search, track, and reference the replenishment.

The purchase order number you assigned when creating the replenishment.

Example: PO-2024-001, ORDER-12345

Use: Correlate with your purchasing records and supplier invoices.

The name of the supplier or distributor from whom you received inventory.

Example: Acme Wholesale, Global Distributors, Internal Transfer

Use: Filter by supplier to see all history from a specific supplier.

The carrier tracking number that delivered the shipment.

Example: 1Z999AA10123456784 (UPS), 9400110200830208562007 (USPS)

Use: To verify delivery information or disputes with carrier.

The final status of the archived replenishment. Icons indicate:

Comments about the replenishment. Can be:

Example: Arrived in 3 pallets, Missing 10 units of SKU-001, Damaged box replaced

The date when the replenishment was created in the system.

Format: YYYY/MM/DD or MM/DD/YYYY HH:MM AM/PM

Example: 2024/03/15 10:30 AM

Use: To know when shipment was ordered or scheduled.

The date when the shipment physically arrived at the warehouse and was marked as “Arrived”.

Format: YYYY/MM/DD HH:MM:SS

Example: 2024/03/22 14:45:00

Use: To calculate transit time and supplier performance.

Note: This date is automatically recorded when warehouse marks replenishment as “Arrived”.

The total monetary value of received inventory, calculated based on:

Format: $X,XXX.XX

Example: $1,250.50, $10,450.00

Use:

Note: This total is calculated based on ACTUALLY received quantities, not expected.

The archived view includes advanced search filters:

= (equals)12345 to search for that specific replenishment= (equals)PO-2024-001 to search for that purchase orderbetween (between)2024/01/01 to 2024/03/31 (Q1 2024)between (between)2024/03/01 to 2024/03/31 (March 2024)In the general search field you can enter any term and search in:

Note: The general search does NOT search by Reple ID. Use the specific Reple ID filter for that.

Search options:

General search example:

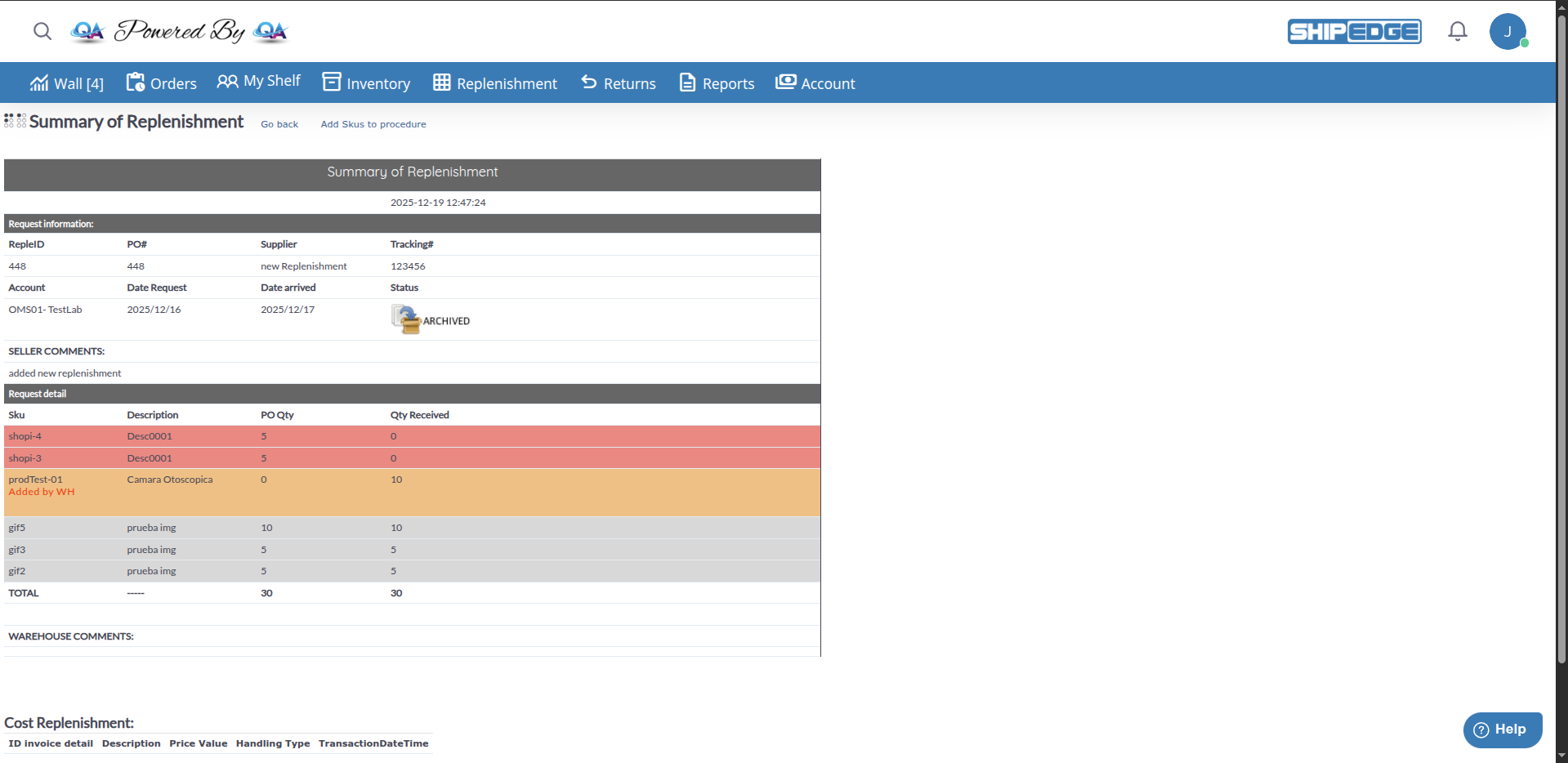

Click the Reple ID

In the archived replenishments table, click the Reple ID (RequestID) number of the replenishment you want to review.

This opens the Summary of Replenishment view.

Request Information Section

At the top of the details view, you’ll see key information about the replenishment:

SELLER COMMENTS Section

Displays comments added by the seller when creating or processing the replenishment. This may include notes about the order, special instructions, or issues encountered.

Request Detail Table

The main table shows all SKUs in the replenishment with:

Color coding:

TOTAL row: Shows sum of PO Qty and Qty Received columns

WAREHOUSE COMMENTS Section

Displays comments added by warehouse staff during receiving and processing. This section may be empty if no warehouse comments were added.

Cost Replenishment Section

Shows cost breakdown information with columns for:

Note: This section may not always display data depending on how costs were recorded.

Available Actions

In the header area, you’ll find:

When you pay the supplier invoice, you can mark the replenishment as paid for accounting control:

Locate Replenishment in Table

Find the replenishment you want to mark as paid.

Requirement: Replenishment must be in status PROCESSED or PARTIALLY PROCESSED.

Click “Archive”

In the last column of the table (Actions column), you’ll see a button that says Archive.

System Updates Status

The system:

Payment Fields:

PAID, NOT_PAID, or PENDINGIf a replenishment was partially processed and you need to order the missing items, you can use the “Re-open” function to create a new replenishment with only the SKUs and quantities that were not received.

Locate Partially Processed Replenishment

Find a replenishment with status PARTIALLY PROCESSED.

Click “Re-open” Link

In the Actions column of the table, you’ll see a link that says “Re-open”.

Note: This link only appears for replenishments with status (PARTIALLY PROCESSED).

Confirm Action

A confirmation dialog appears: “This action will create a new replenishment with the SKUs and Quantities not received. Proceed?”

Click OK to confirm.

New Replenishment Created

The system:

Process New Replenishment

Use Cases:

Scenario: Need to know all inventory that arrived in March for a monthly report.

2024/03/012024/03/31Result: Complete list of March receipts with total values.

Scenario: Received an invoice from supplier “Acme Wholesale” for $5,450.00 corresponding to PO# PO-2024-Q1-005. Need to verify everything matches before paying.

PO-2024-Q1-005

Result: Invoice verified and marked as paid in system.

Scenario: Want to analyze if supplier “Global Distributors” delivers on time and complete.

Global DistributorsResult: Data to evaluate performance and negotiate better terms with supplier.

Scenario: A customer claims they never received a product you supposedly had in stock since February. Need to verify if you actually received it from supplier.

WIDGET-0012024/02/01 to 2024/02/29 (February)WIDGET-001 is in list of received SKUsResult: Documentary evidence of when and how much inventory was received to resolve disputes.

Scenario: End of fiscal year - need a complete report of all inventory purchases for the year.

2024/01/012024/12/31Result: Complete annual inventory investment report ready to present to finance or audit.

Archived replenishments have three payment statuses:

SW_PAGADO: NOT_PAID or empty

Meaning: Supplier invoice hasn’t been paid yet.

Action: Review invoice, process payment when appropriate, and mark as PAID.

SW_PAGADO: PENDING

Meaning: Payment is in process (check issued, transfer scheduled, awaiting approval).

Action: Once payment completes, mark as PAID.

SW_PAGADO: PAID

Meaning: Supplier invoice was paid completely.

Action: None. Replenishment is closed and paid.

When you pay a supplier invoice, mark the replenishment as PAID the same day. Avoids confusion and duplicate payments.

Use a standard numbering system for PO#. Facilitates searches and correlation with your accounting system.

Before paying supplier invoice, review archived replenishment to confirm you received everything invoiced.

At end of each month, export archived replenishments from the month to CSV and save as backup for accounting records.

Each quarter, review supplier performance using archived replenishments: punctuality, completeness, costs.

When processing replenishments, add comments about problems, damage, or discrepancies. These comments will be visible in archived.

Problem: Searching for a specific replenishment but it doesn’t appear in archived list.

Possible Causes:

Solutions:

Problem: Total $ shown in archived is different from supplier invoice amount.

Common Causes:

Solutions:

Problem: Don’t see “Archive” link to mark as paid.

Possible Causes:

Solutions:

| Aspect | Active Replenishments | Archived Replenishments |

|---|---|---|

| Status | INCOMPLETE, IN-TRANSIT, ARRIVED | PROCESSED, PARTIALLY PROCESSED, ARCHIVED/PAID |

| Action | Can be edited, received, processed | Read-only (generally) |

| Purpose | Work in progress | History and audit |

| Mark as PAID | Not available | Available (“Archive” link for status PROCESSED or PARTIALLY PROCESSED) |

| Re-open | Not applicable | Available (“Re-open” link for status PARTIALLY PROCESSED only) |

| Quantity | A few (current shipments) | Thousands (all history) |

| Filter | Shows all active statuses | PROCESSED, PARTIALLY PROCESSED, ARCHIVED/PAID |

See Also:

Complete Replenishment Process:

Reports and Analysis:

All history is preserved indefinitely, providing complete transparency and traceability of your supply chain.